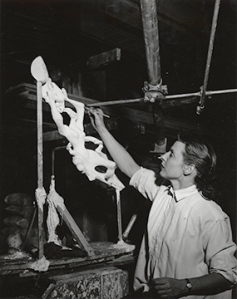

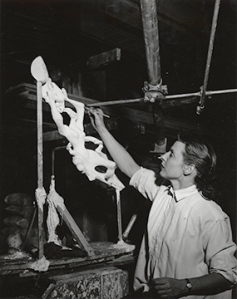

I went to a demonstration of 3D printers recently, and ended up thinking about this photograph of Gwen Lux in her New York studio sometime in the 1940s. Lux is seen enlarging her sculpture for Rockefeller Center using a pantograph, the assemblage of pipes above her head. While the Juley Archive of the Smithsonian houses this and other photographs of Lux with her sculpture (both maquette and full-scale versions), her pantograph is only visible in this shot. A construction of metal and pipe, rigged on a boom near the studio ceiling, it basically worked just like the child’s toy that many of us used to make copies long before the existence of desktop 3D printers.

I went to a demonstration of 3D printers recently, and ended up thinking about this photograph of Gwen Lux in her New York studio sometime in the 1940s. Lux is seen enlarging her sculpture for Rockefeller Center using a pantograph, the assemblage of pipes above her head. While the Juley Archive of the Smithsonian houses this and other photographs of Lux with her sculpture (both maquette and full-scale versions), her pantograph is only visible in this shot. A construction of metal and pipe, rigged on a boom near the studio ceiling, it basically worked just like the child’s toy that many of us used to make copies long before the existence of desktop 3D printers.

The pantograph’s basic design is simple: four bars linked together in a parallelogram shape. By tracing an object or drawing with the pointer end, the pantograph traces a larger or smaller image depending upon how one adjusts the pen (or pencil) and pointer.

Wikipedia says that the device was first created by inventor and steam pioneer James Watt in the 18th century, but other, simpler versions were in use by artists in the Renaissance and probably before. Watt’s version was perfected by Benjamin Cheverton (1796–1876) in 1836. Cheverton’s machine was fitted with a rotating cutting bit to carve reduced versions of well-known sculptures.

Another version is still in use to reduce the size of large relief designs for coins.

http://www.rockefellercenter.com/art-and-history/

http://ids.si.edu/ids/deliveryService?id=SAAM-J0001885

A recent visit to

A recent visit to